Product Details

We focus on the field of pcb manufacturing and pcb assembly for more than 20+ years,and we have ISO9001 quality management system certification,ROSH,ISO14001 environmental management system certification,

TS16949 automobile quality management system certification and other certification.

For the aerospace industry has numerous applications, it likes:

Flight Control Systems: PCB assembly is extensively used in flight control systems, which are responsible for controlling the aircraft’s movement, stability, and navigation. These systems require high reliability, precision, and fast data processing capabilities, which can be achieved through advanced PCB assembly techniques.

Avionics Systems: Avionics systems in aerospace applications rely heavily on PCB assembly. These systems include communication systems, navigation systems, radar systems, and instrumentation systems. PCB assembly enables the integration of complex electronic components and ensures the efficient functioning of these critical systems.

Satellite Systems: PCB assembly is crucial in satellite systems used in aerospace applications. Satellites require highly reliable and compact PCB assemblies for various functions, including communication, data processing, power management, and control systems.

Onboard Electronics: PCB assembly is used in various onboard electronics systems, such as lighting systems, entertainment systems, cabin management systems, and environmental control systems. These systems enhance passenger comfort and safety during flights.

Data Acquisition and Recording: PCB assembly is utilized in aerospace applications for data acquisition and recording systems. These systems collect and record data from various sensors and instruments onboard the aircraft, providing valuable information for analysis, maintenance, and safety purposes.

Power Distribution Systems: PCB assembly is employed in power distribution systems within aerospace applications. These systems manage and distribute electrical power to different aircraft systems and components, ensuring efficient and reliable power supply.

In-flight Communication Systems: PCB assembly is used in in-flight communication systems, including radio communication, satellite communication, and onboard Wi-Fi systems. These systems enable communication between the aircraft and ground stations, as well as provide connectivity options for passengers.

Safety and Monitoring Systems: PCB assembly is utilized in safety and monitoring systems, such as fire detection and suppression systems, smoke detection systems, and aircraft health monitoring systems. These systems ensure the safety and well-being of passengers and crew members.

Overall, PCB assembly plays a critical role in the aerospace industry by enabling the integration of complex electronic systems, ensuring reliable communication, enhancing safety, and improving the overall performance of aircraft and satellite systems.

As Below is our capability of the pcb fabrication and pcb assembly, if there's any request on PCB products, please send us a quote, we'll do our best to answer you within 12 hours.

| Item | Flexible pcb | Rigid-Flexible pcb | Rigid PCB |

| Max Layer | 8L | 36L | 60L |

| Inner Layer Min Trace/Space | 3/3mil | 3/3mil | 3/3mil |

| Out Layer Min Trace/Space | 3.5/4mil | 3.5/4mil | 3/3mil |

| Inner Layer Max Copper | 2oz | 6oz | 6oz |

| Out Layer Max Copper | 2oz | 3oz | 6oz |

| Min Mechanical Drilling | 0.1mm | 0.15mm | 0.15mm |

| Min Laser Drilling | 0.1mm | 0.1mm | 0.1mm |

| Aspect Ratio(Mechanical Drilling) | 10:1 | 12:1 | 20:1 |

| Aspect Ratio(Laser Drilling) | / | 1:1 | 1:1 |

| Press Fit Hole Ttolerance | ±0.05mm | ±0.05mm | ±0.05mm |

| PTH Tolerance | ±0.075mm | ±0.075mm | ±0.075mm |

| NPTH Tolerance | ±0.05mm | ±0.05mm | ±0.05mm |

| Countersink Tolerance | ±0.15mm | ±0.15mm | ±0.15mm |

| Board Thickness | 0.1-0.5mm | ±0.1mm | 0.4-8mm |

| Board Thickness Tolerance(<1.0mm) | ±0.05mm | ±0.1mm | ±0.1mm |

| Board Thickness Tolerance(≥1.0mm) | / | ±10% | ±10% |

| Impedance Tolerance | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) | Single-Ended:±5Ω(≤50Ω),±7%(>50Ω) |

| Differential:±5Ω(≤50Ω),±10%(>50Ω) | Differential:±5Ω(≤50Ω),±10%(>50Ω) | Differential:±5Ω(≤50Ω),±7%(>50Ω) | |

| Min Board Size | 5*10mm | 10*10mm | 10*10mm |

| Max Board Size | 9*14inch | 22.5*30inch | 22.5*30inch |

| Contour Tolerance | ±0.05mm | ±0.1mm | ±0.1mm |

| Min BGA | 7mil | 7mil | 7mil |

| Min SMT | 7*10mil | 7*10mil | 7*10mil |

| Surface Treatment | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

| Solder Mask | Green Solder Mask/Black PI/Yellow PI | Green Solder Mask/Black PI/Yellow PI | Green,Black,Blue,Red,Matt Green |

| Min Solder Mask Clearance | 3mil | 1.5mil | 1.5mil |

| Min Solder Mask Dam | 8mil | 3mil | 3mil |

| Legend | White,Black,Red,Yellow | White,Black,Red,Yellow | White,Black,Red,Yellow |

| Min Legend Width/Height | 4/23mil | 4/23mil | 4/23mil |

| Strain Fillet Width | 1.5±0.5mm | 1.5±0.5mm | / |

| Bow & Twist | / | 0.05% | 0.3% |

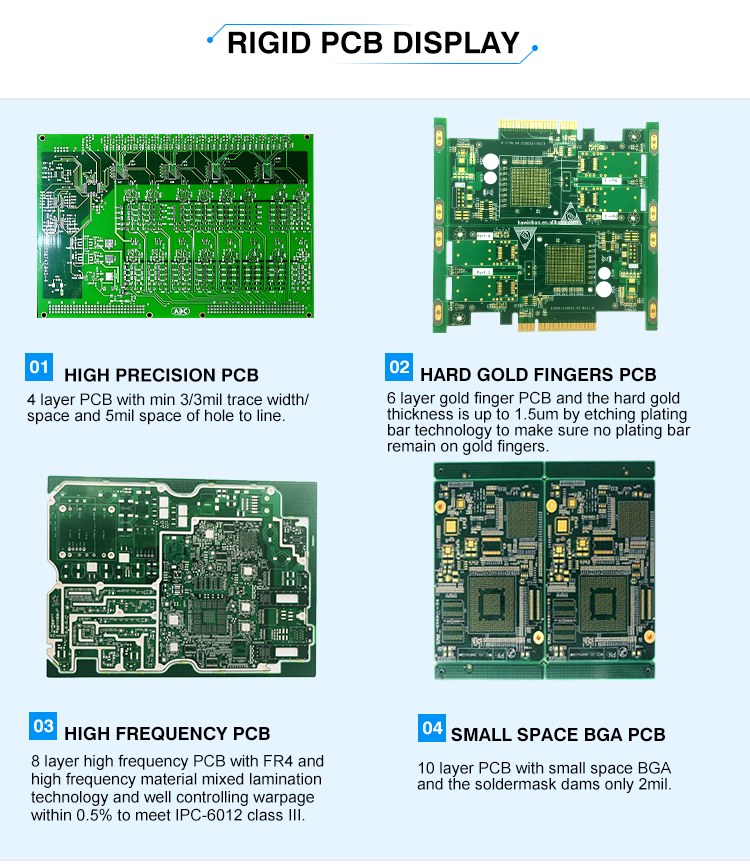

Rigid pcb also includes high precision pcb,hard gold fingers pcb,high frequency pcb,small saplce bga pcb.

The high precision pcb:4 layer pcb with min 3/3mil trace wideth/space and 5 mil space of hole to line.

Hard gold fingers pcb: 6 layer gold finger pcb and the hard gold thickness is up to 1.5um by etching plating bar technology

to make sure no plating bar remain on gold fingers.

High frequency pcb:8 layer high frequency pcb with fr4 and high frequency material mixed lamination technology and well

controlling warpage within 0.5% to meet IPC-6012 Class Ⅲ.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China