A PCB is a blank circuit board, while a PCBA is a board that contains all the necessary electronic components to make the board function as needed. Whereas a PCBA is a complete functional board, a PCB and a PCBA are two different parts of the same process - a PCBA is built on top of an existing PCB.

In this guide, we will learn more about the definition of a PCB, the definition of a PCBA, and the differences between the two terms.

PCBs are the foundation of modern electronic devices. They support and electrically connect electronic components in a mechanical way. The circuit board itself is made of laminated material, such as glass fiber or composite epoxy, and contains conductive paths connecting different parts of the board. Depending on the intended PCB design, these paths are printed or etched on the board.

The main types of PCBs include.

Single-layer PCBs are the simplest type of PCB, coated with a single layer of conductive material and a solder resist layer. the components of the PCB are marked with silkscreen.

Double-layer PCBs have a layer of conductive material on both the top and bottom of the board, which gives them greater flexibility and smaller size than single-layer PCBs.

Multilayer PCBs have more than two conductive layers and are used for more complex applications.

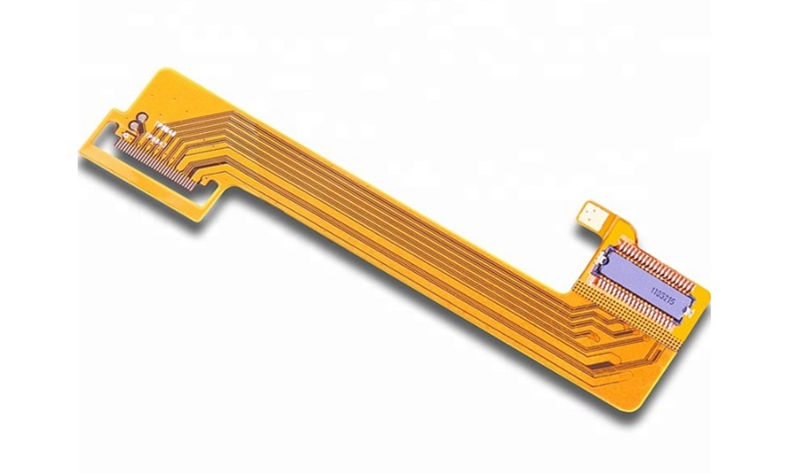

Other common types of PCBs include flexible PCBs, rigid PCBs, and flexible-rigid PCBs.

While a PCB refers to a blank board, a PCBA is a complete PCB assembly that contains all the electronic components needed to make the board function as required.PCBA may also refer to the process of assembling the board with the necessary components.

PCBA companies can use two main methods for PCB assembly.

Surface Mount Technology (SMT) is an assembly process that involves mounting electronic components onto the PCB surface. It is highly automated and flexible, and allows for higher connection densities. It allows manufacturers to place complex circuits into small components.

Through-hole technology is an assembly process that involves drilling holes in a PCB through which electronic components called leads can be connected. It is a much older technology than SMT, but creates a stronger connection between the board and the component, resulting in a more durable and reliable assembly. Through-hole assembly can be fully or semi-automatic.

PCB and PCBA are the result of two different steps of the same overall process. a PCB is a blank circuit board with no electronic components attached, while a PCBA is a complete assembly containing all the components required by the board according to the desired application. a PCB is not yet functional, while a PCBA is ready to be used in electronic devices.

Due to the various components and processes involved in PCB assembly, manufacturing a blank board is easier than producing a complete PCBA. It is also more expensive to produce a PCBA than a blank PCB. However, both steps are necessary to create a complete board. PCB manufacturing is the first step in the process, and PCBA manufacturing builds on that first step.

If you have any questions, welcome to contact TOPFAST, we offer custom solution for you!

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

4/F, Building 21, No. 46 Xinye Road, Yonghe Development Zone, Huangpu District, Guangzhou, China

Office Address:

Room 2201-03 & 2206, Building 1, Changfeng International, No. 96, Li Xin 12 Road, Zengcheng District, Guangzhou City, Guangdong Province, China.