Ceramic PCB as a newer printed circuit board, has been widely used in the electronics industry for many years, is a more viable option for PCB designers, and is considered an effective solution product for modern electronics to achieve miniaturization and electronic assembly technology. You will find that ceramic PCBs have advantages over traditional printed circuit boards. TOPFAST takes a look at it.

Ceramic PCB is a ceramic-based printed circuit board, which is a highly thermally conductive material such as aluminum oxide, aluminum nitride, beryllium oxide, etc. It can quickly transfer heat from hot spots and dissipate it. It covers the entire surface. What's more, ceramic PCBs are manufactured using LAM technology, which is a laser rapid activation metallization technology. As a result, ceramic PCBs are highly versatile and can replace entire conventional printed circuit boards with a simpler structure and enhanced performance.

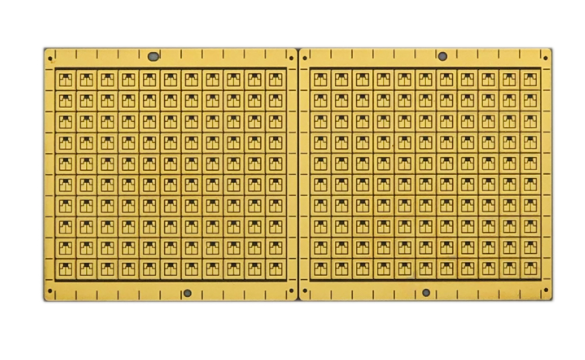

Deep Ultraviolet Pcb Water Purifier

Heat dissipation is a major advantage of ceramics over more traditional materials such as FR-4 and metal clad PCBs. Compared to conventional PCBs where the substrate material is epoxy glass fiber, polyimide, polystyrene and phenolic resin, ceramic PCBs have the following properties.

One of the reasons ceramic PCBs are widely used in the electronics industry is because they have a high coefficient of thermal expansion. The thermal conductivity of ceramic substrates is very close to that of silicon, while under most of the connection metals used. Needless to say, it can function as an excellent isolator for a long time. As a result, the high thermal conductivity of ceramic PCBs provides optimal performance even at high temperatures and can therefore be used in many devices.

Due to the use of ceramics, the dielectric properties are stable and the balance can be turned into limited RF loss, increasing the suitability for electronic devices. More importantly, despite the external toughness, ceramics are naturally resistant to most chemicals used due to ceramic substrate PCBs. Thus, the resistance to chemicals will become resistance to everyday moisture, solvents and consumables.

It is no wonder that the addition of metal core PCBs allows for many high melting point applications. Thanks to sintering technology, precious metal pastes can become highly reliable conductors. Therefore, there is no doubt that the use of ceramic PCBs affects high processing temperatures, and different devices are suitable for different operating temperatures. Interestingly, it also allows good thermal conductivity and heat distribution to different locations of the device.

As you know, ceramic PCB manufacturing processes are durable. Thanks to the basic properties of ceramic, especially the toughness, you can be sure that your boards are protected against daily wear and tear. Due to its rather slow aging characteristics, ceramic PCBs are consistent with the base PCB and can be replaced without having to worry about replacing them anytime soon. What's more, it has high heat resistance as it can be transformed into a slow decomposition process, thus extending the service life.

Finally, one of the outstanding advantages of ceramic PCBs is the use of metal cores in the engineering process. It can be converted into a rigid carrier, providing mechanical stiffness, making it easy to use between fluids and solids, with good roughness and wear resistance, so it can be used in a variety of industrial applications.

Please follow manufacturer TOPFAST to get your custom PCB boards and designs. We welcome your inquiry.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

4/F, Building 21, No. 46 Xinye Road, Yonghe Development Zone, Huangpu District, Guangzhou, China

Office Address:

Room 2201-03 & 2206, Building 1, Changfeng International, No. 96, Li Xin 12 Road, Zengcheng District, Guangzhou City, Guangdong Province, China.