To understand the difference between PCB core and prepreg materials, it is important to understand what each of them is. PCB manufacturer shows you.

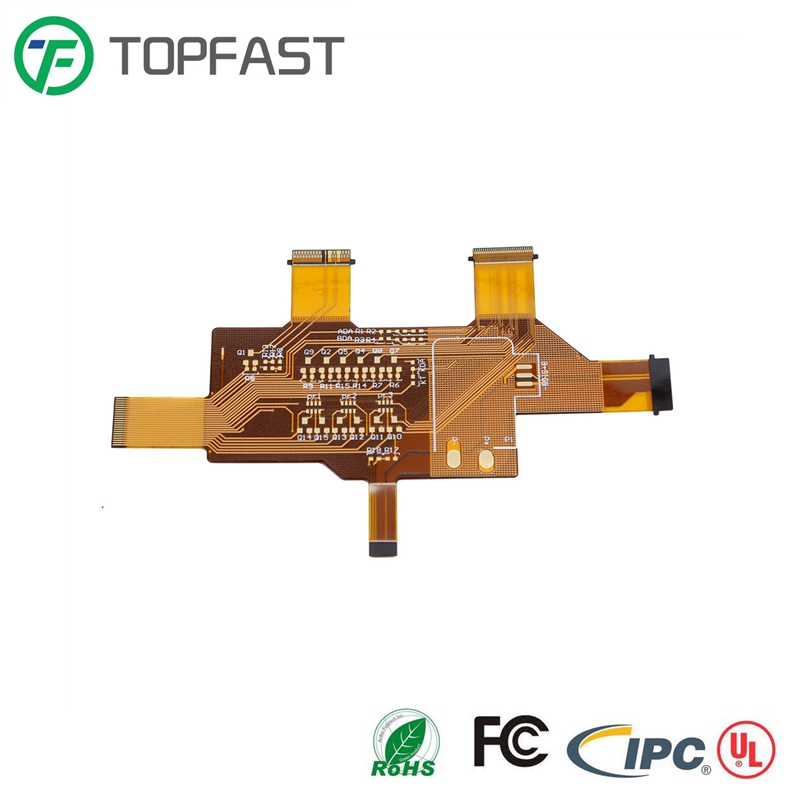

In short, prepreg is a conductive substance used to provide proper insulation between copper and PCB cores. It is a dielectric material that is sandwiched between two cores, i.e. a core and a copper foil. It is often referred to as an adhesive material because it bonds two cores or a core and a copper foil.

As the name implies, prepreg is a glass fiber impregnated with a resin binder. All prepregs are Stage B materials. There are different types of prepregs, depending on their thickness and the resin content they hold.

A typical prepreg preparation process consists of

Reinforcement with resin

Removal of excess resin

Preparation using high and low temperature settings for curing

Prepreg is an important part of the PCB manufacturing process for several reasons.

It is easy to apply and use. It is easy to get used to and does not require much technical expertise.

It is not messy compared to wet layup. Therefore, waste management in the manufacturing process is effective.

A wide range of prepreg is available to meet different requirements.

It helps to reduce the weight of the equipment and is therefore particularly useful in an environment where miniaturization of equipment has become the norm.

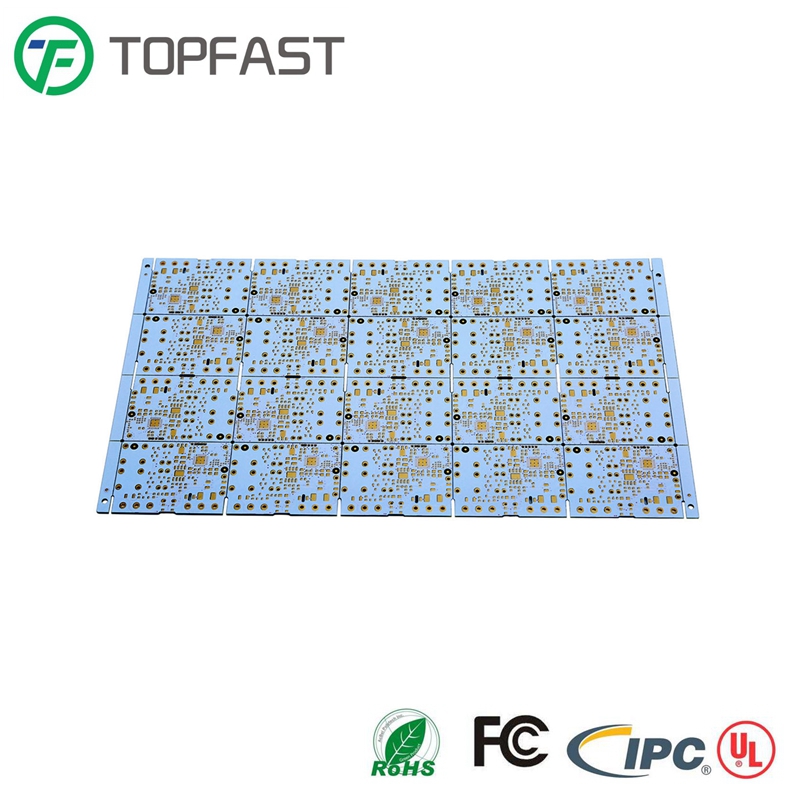

The core of a PCB is a rigid substrate laminated with copper. It is used to manufacture single-sided or double-sided circuit boards as well as multilayer PCBs. multilayer PCBs have the following components.

Copper foil, prepreg, copper foil, core material, copper foil, prepreg, copper foil.

There is often confusion between prepreg and core due to the similarities between the two. Simply put, the core is the product of prepreg and lamination. As such, it is much more rigid compared to prepreg. The core consists of a glass fiber epoxy laminate that is flame retardant and has copper on both sides.

On the other hand, the prepreg is partially dry without lamination and is not as stiff as the core.

Another important difference between PCB prepregs and cores is their dielectric constants. While the dielectric constant of the core remains unchanged, the dielectric constant of the prepreg changes before and after lamination.

The thickness of the PCB is a function of the prepreg used. In fact, the desired thickness can be achieved by a combination of prepreg layers, i.e., by placing a thin slice of prepreg on top of another.

Under high voltage, creepage and leakage currents are a problem regardless of the PCB core or prepreg used. The electromigration of copper and the growth of conductive filaments require creepage distance specifications for FR4 materials. Due to this issue and to increase the glass transition temperature and decomposition temperature, there has been a shift to non-dicyandiamide resins.

Both core and prepreg are important components of a PCB. While the core is the base PCB material, the multi-layer PCB is held together by the prepreg. The difference between the two is that the core is cured, while the prepreg material is ductile, which means it can be easily molded into sheets. When subjected to high temperatures, the material melts, helping to fuse the layers together.

With years of combined experience in providing high quality and standard PCB assembly and manufacturing services, we offer unparalleled technical expertise and state-of-the-art solutions. At TOPFAST, we specialize in a variety of PCB manufacturing processes using advanced PCB production technologies and manufacturing practices. Contact us for a partnership!

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

4/F, Building 21, No. 46 Xinye Road, Yonghe Development Zone, Huangpu District, Guangzhou, China

Office Address:

Room 2201-03 & 2206, Building 1, Changfeng International, No. 96, Li Xin 12 Road, Zengcheng District, Guangzhou City, Guangdong Province, China.