Although PCBs have been in usage for decades, they are finding new applications in numerous commercial markets. With developments in CNC devices, making procedures, as well as the huge demand for smaller sized boards with several elements, PCB layouts ought to have the ability to take care of high voltage, high power boards with numerous layers, and so on. This essay talks about the developments in PCB manufacturing processes.

Advanced PCBs often have special features such as really limited soldermask offset tolerances, minimum trace sizes without filler lines, blocked vias, extremely limited dimensional precision, as well as a lot more. These are generally used in electronic devices and also telecommunications, instrumentation, biomedical, defense, commercial devices, and so on. Lots of advancements are still being examined as PCB manufacturing processes, products, parts as well as equipment need to remain to improve and also develop.

Here are some appropriate existing fads.

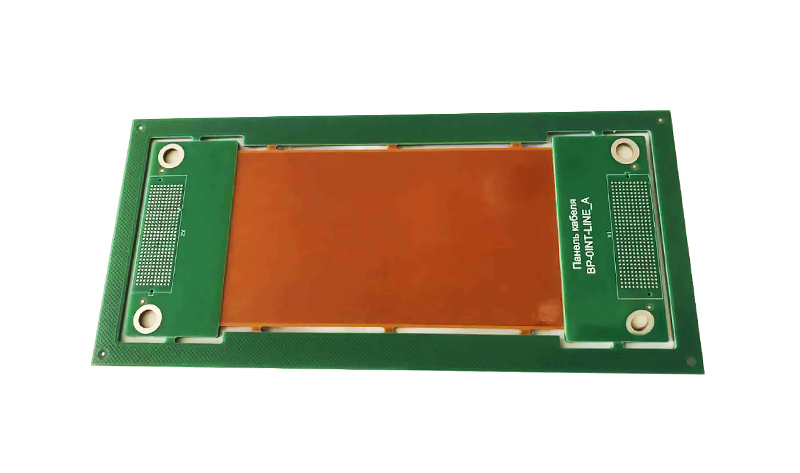

As opposed to rigid or rigid-flexible circuit boards, it is popular because of the use of fully adaptable circuit boards. This is mostly because of the bending angle as well as flexibility they use. They can be made in little sizes, while still accommodating numerous components and layers. On top of that, you can pick materials that can stand up to extreme settings.

Double-Sided Rigid-Flex PCB

Modern PCBs have an autorouter or autorouter in their design, which assists in automation by automatically transmitting electronic functions throughout the board to determine PCB layout functions. This element speeds up the automation of the product. Nonetheless, it requires additional research study to simplify setup as well as arrangement in addition to meet certain product layout requirements.

These are electronic cameras that are placed directly on the PCB. They are small in dimension and can for that reason be quickly mounted on the board. They can quickly take high definition pictures as well as videos. Additional research study may generate better results, which might help enhance industrial options as well as other applications.

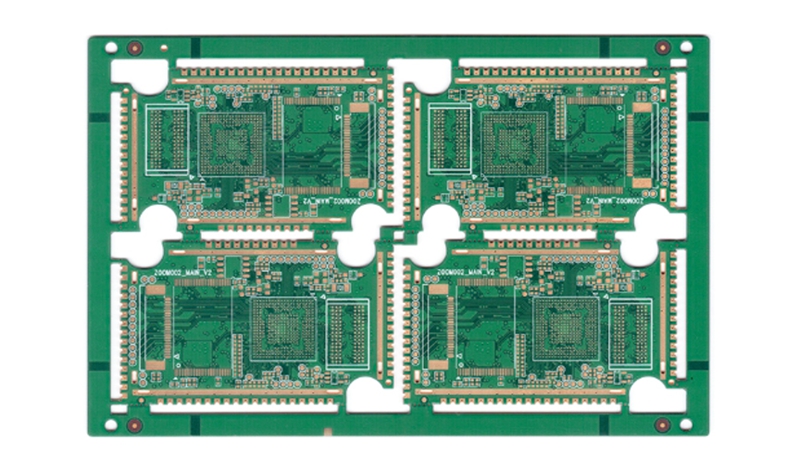

This has actually been widely utilized and remains in great need as electronic tools continue to shrink in size. This technology assists in high-speed signal transmission on portable boards with a minimal number of layers.

HDI PCB

Smart tools from phones and also meters to fridges, lighting systems, as well as other home and also industrial systems are all part of the IoT. These wise devices run in automated mode, sense things, and also send out suitable messages as well as signals, thanks to their intricate PCB layouts.

These boards are provided with voltages up to 48 volts. These are normally made use of in electric cars where need is quite high and anticipated to boost additionally. However, in order to get rid of sound and interference issues, these boards need the installation of huge elements, consisting of battery packs.

Ensure you work with a trustworthy PCB supplier as well as provider, TOPFAST has years of experience and makes use of advanced PCB production processes. We can manufacture all kinds of dif-ficult Rigid-Flex boards, includingstep structure Rigid-Flex PCB.flyingtail structure Rigid-Flex PCB.layered flexible PCB,non-layeredilexible PCB, etc. Send a message to sales@topfastpcb.com, or call +86 17702089421 to find more.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China