Choosing the right PCB manufacturer for your equipment is not always easy, the right PCB manufacturer can make your work process easier, but the wrong manufacturer can cause a lot of grief. Therefore it is worthwhile to do some research on different PCB manufacturers, it usually helps to get some guidance for decision-making.

Printed circuit boards are one of the most important features of electronic assemblies. PCBs provide mechanical support and connections for electronic devices. PCBs come in several different technologies, depending on the application. Some examples are stiffener PCB, double-sided flexible PCB, FR4 stiffener flexible PCB, PCBA board, and 3m stiffener flexible PCB. The type and quality of the PCB affect the functionality of the electronic device, which is why you should be careful when choosing a PCB manufacturer. There are six aspects that should normally be considered when choosing a manufacturer.

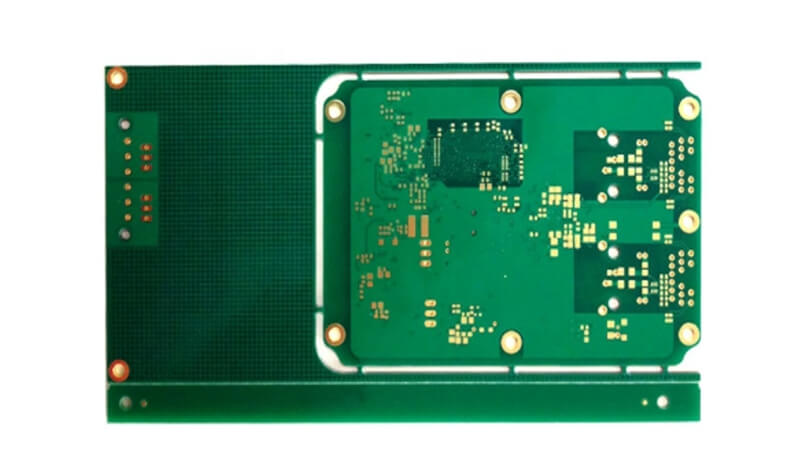

PCB Equipment

Quality is a key issue when choosing the right PCB manufacturer. PCB quality can mean a number of different things:

Board to the correct size

All holes are drilled and accurately positioned

Passing bare board tests

Minimal board warpage (although some of this may be due to board design)

Quality has to be consistent, not falling off after a successful mains order has been obtained, material compliance, etc.

As errors can jeopardize the business of a PCB assembly or equipment manufacturer, ensuring the quality of the chosen supplier is key. Consistent quality can be asked of other non-competing companies that may use them.

Rigid PCB

The ability of companies to collaborate and build relationships is another key factor. This is difficult to quantify, but if PCB manufacturers are able to work together with the PCB assembly and design areas, then synergies can provide significant advantages, with partnerships helping to resolve issues quickly and helping to provide feedback to improve processes and productivity to the benefit of all parties.

Price is always a factor that must be considered. Of course, you want to minimize costs, but you also have to be careful that the quality of the board is adequate, so balancing cost and quality is essential to achieve the lowest possible price for the required product. You need to find a manufacturer that offers a product that meets your quality standards while remaining within your price range.

One aspect to consider is the initial offer. Once you have provided the manufacturer with information about your project, they will be able to provide you with a quote. To ensure that the quote they give you is a realistic estimate of the total cost, ask if any other costs will be added later on in the order process.

Also, ask the manufacturer if they will offer discounts or special offers for bulk orders or multiple orders to ensure you get the best price.

Ensuring that project deadlines can be met is a major factor to consider when choosing a PCB manufacturer. In many cases, on-time delivery falls into the quality category. However, it is important to ensure that the PCB company you choose has a track record and can prove that they can provide an accurate delivery time and deliver within that delivery time. However, sometimes the time required to manufacture a PCB may not be the main issue and it is also useful to be able to deliver boards at a quick turnaround. The success of your project may depend on these results.

It may be surprising that many so-called PCB manufacturers simply take orders and pass them on to the company that will manufacture them. But this may be the reason why there is no guarantee of the standards and requirements that need to be put on the board. So it is best to ensure that there is communication with the actual PCB manufacturer.

Certification provides additional insight into the manufacturer's level of conformity. To ensure that the manufacturer you are considering working with is able to comply with all standards applicable to your industry and product, you must consider the manufacturer's Quality Management System (QMS). The International Organisation for Standardisation (ISO) publishes standards relating to quality management, such as ISO 9001, as well as other areas. Depending on your requirements, you can expect your manufacturer to have at least ISO 9001 certification and the Restriction of Hazardous Substances (RoHS).

Other certifications that may help demonstrate competence include ISO 13485 (medical), ISO 14001, TS16949, CE, and UL. All of these should be provided by the manufacturer for review.

ISO 9001

PCBs may appear to be just another commodity purchased by the assembly plant. However, PCBs are vital to the optimum performance of any electronic device. The ones mentioned here are just a few suggestions that you may wish to consider in your selection process. When it comes to quality, you should never compromise, choose wisely and do your due diligence.

Finally, you will realize that choosing the right PCB manufacturer is essential for effective electronic equipment.

For more information, to order or for a quote, please visit this link.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

4/F, Building 21, No. 46 Xinye Road, Yonghe Development Zone, Huangpu District, Guangzhou, China

Office Address:

Room 2201-03 & 2206, Building 1, Changfeng International, No. 96, Li Xin 12 Road, Zengcheng District, Guangzhou City, Guangdong Province, China.