Product Details

Double Sided Printed Circuit Boards offer two conductor layers separated by a dielectric, usually polyimide. Coverlayers may be used on one or both sides. Plated through holes may or may not be featured to interconnect traces on opposite sides of the dielectric.Double Sided Printed Circuit Board provides the ability to access circuit traces from both the top and bottom sides of the circuit offering greater flexibility in design and functionality. Properly designed and utilized, Double Sided Printed Circuit Boards offer the same level of dynamic flexing (repetitive movement) as do single-sided flex, providing a much wider range of application uses due to its ability to carry more complex circuit layouts.

| Item | Rigid-Flexible PCB | Flexible PCB |

| Max Layer | 36L | 8L |

| Inner Layer Min Trace/Space | 3/3mil | 3/3mil |

| Out Layer Min Trace/Space | 3.5/4mil | 3.5/4mil |

| Inner Layer Max Copper | 6oz | 2oz |

| Out Layer Max Copper | 3oz | 2oz |

| Min Mechanical Drilling | 0.15mm | 0.1mm |

| Min Laser Drilling | 0.1mm | 0.1mm |

| Aspect Ratio(Mechanical Drilling) | 12:1 | 10:1 |

| Aspect Ratio(Laser Drilling) | 1:1 | / |

| Press Fit Hole Ttolerance | ±0.05mm | ±0.05mm |

| PTH Tolerance | ±0.075mm | ±0.075mm |

| NPTH Tolerance | ±0.05mm | ±0.05mm |

| Countersink Tolerance | ±0.15mm | ±0.15mm |

| Board Thickness | 0.4-3mm | 0.1-0.5mm |

| Board Thickness Tolerance(<1.0mm) | ±0.1mm | ±0.05mm |

| Board Thickness Tolerance(≥1.0mm) | ±10% | / |

| Impedance Tolerance | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) |

| Differential:±5Ω(≤50Ω),±10%(>50Ω) | Differential:±5Ω(≤50Ω),±10%(>50Ω) | |

| Min Board Size | 10*10mm | 5*10mm |

| Max Board Size | 22.5*30inch | 9*14inch |

| Contour Tolerance | ±0.1mm | ±0.05mm |

| Min BGA | 7mil | 7mil |

| Min SMT | 7*10mil | 7*10mil |

| Surface Treatment | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

| Solder Mask | Green,Black,Blue,Red,Matt Green | Green Solder Mask/Black PI/Yellow PI |

| Min Solder Mask Clearance | 1.5mil | 3mil |

| Min Solder Mask Dam | 3mil | 8mil |

| Legend | White,Black,Red,Yellow | White,Black,Red,Yellow |

| Min Legend Width/Height | 4/23mil | 4/23mil |

| Strain Fillet Width | 1.5±0.5mm | 1.5+0.5mil |

| Bow & Twist | 0.05% | / |

When to use Double Sided Rigid-Flex PCB

1. Required when circuit density and layout can not be routed on a single layer

2. Ground and power plane applications

3. Used for shielding applications

4. Dense surface mount assembly

5. Double-Sided Features

6. Component assembly available on both sides

7. Two conductive layers

8. Can be converted into a Sculptured Flex

Space-saving:

Double-sided rigid-flex PCBs allow for compact designs by combining both rigid and flexible sections into a single board. This saves space compared to using separate rigid and flexible boards.

Improved reliability:

Rigid-flex PCBs offer improved reliability compared to traditional rigid PCBs. The flexible sections provide better resistance to vibrations, shocks, and thermal expansion, reducing the risk of component failure.

Enhanced design flexibility:

Double-sided rigid-flex PCBs offer greater design flexibility compared to rigid PCBs. The flexible sections can be bent, folded, or twisted to fit into tight spaces or irregular shapes, allowing for more creative and innovative designs.

Reduced assembly time and cost:

By combining rigid and flexible sections into a single board, the assembly process is simplified, leading to reduced assembly time and cost. There is no need for separate connectors or cables to connect rigid and flexible boards.

Improved signal integrity:

Double-sided rigid-flex PCBs offer better signal integrity compared to using separate rigid and flexible boards. The shorter interconnects and reduced number of connectors result in lower signal loss and improved signal quality.

Increased durability:

Rigid-flex PCBs are more durable compared to traditional rigid PCBs. The flexible sections can withstand repeated bending and flexing without compromising the integrity of the circuit, making them suitable for applications with high mechanical stress.

Portable Electronics:

Double-sided rigid-flex PCBs are commonly used in portable electronic devices such as smartphones, tablets, and wearable devices. The flexible sections allow for compact and lightweight designs, while the rigid sections provide stability and support for components.

Medical Devices:

Rigid-flex PCBs are often used in medical devices where space is limited and reliability is crucial. They can be used in devices such as pacemakers, hearing aids, and medical implants.

Aerospace and Defense:

Rigid-flex PCBs are used in aerospace and defense applications where there is a need for lightweight and compact designs. They are commonly used in avionics systems, satellites, and military equipment.

Automotive Electronics:

Rigid-flex PCBs are used in automotive electronics where there is a need for flexible connections in areas with vibrations and temperature variations. They are commonly used in dashboard controls, infotainment systems, and engine control units.

Industrial Equipment:

Rigid-flex PCBs are used in industrial equipment where there is a need for reliable and durable circuit boards. They are commonly used in control systems, robotics, and automation equipment.

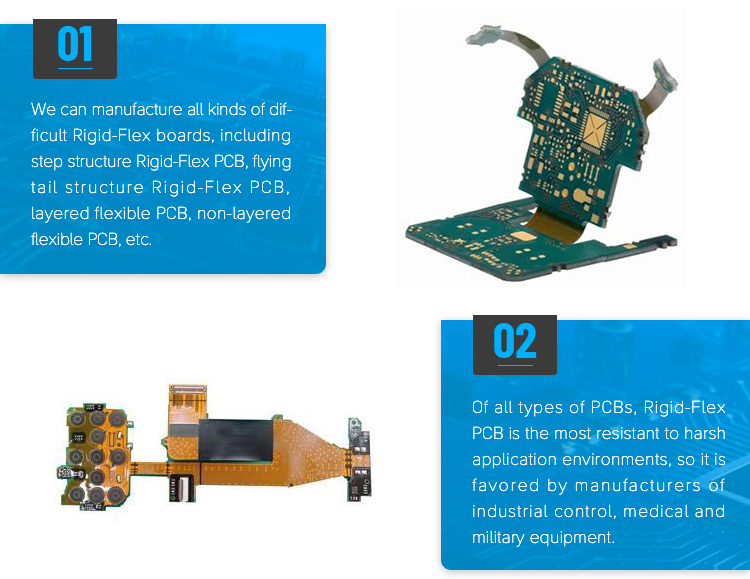

1. We can manufacture all kinds of difficult Double Sided Flex Pcbs and Rigid Circuit Boards , including step structure Rigid-Flex PCB, flying tail structure Rigid-Flex PCB, layered flexible PCB, non-layer edilexible PCB and etc,.

2. Of all types of PCBs, we can provide the most Double Sided Flex Pcb and Rigid Circuit Boards,which is resistant to harsh application environments. As a result, Double Sided Rigid-Flex PCB is favored by manufacturers of industrial control, medical and military equipment.

TOPFAST focus on the field of Flex Printed Circuit Board more than 20+ years,and we have ISO9001 quality management system certification, rosh, ISO14001 environmental management system certification, TS16949 automobile quality management system certification and other certification. Welcome to CONTACT US if you are interested in our products.

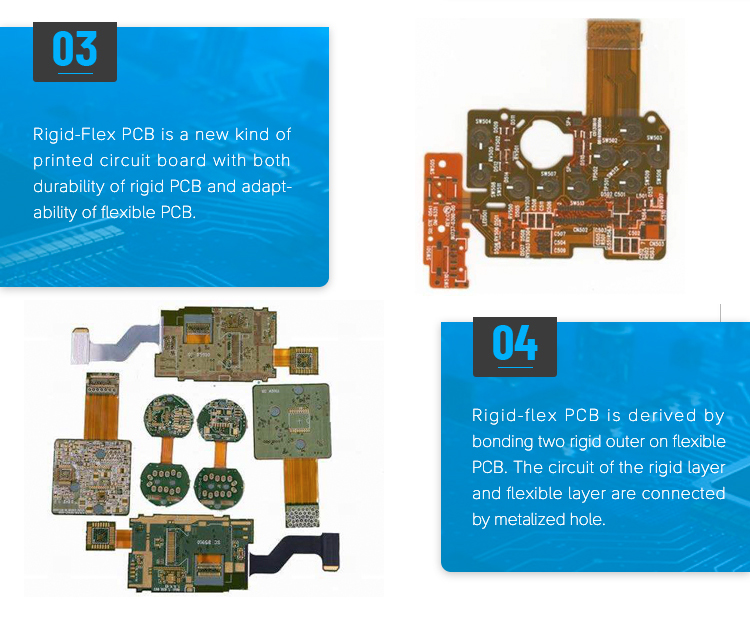

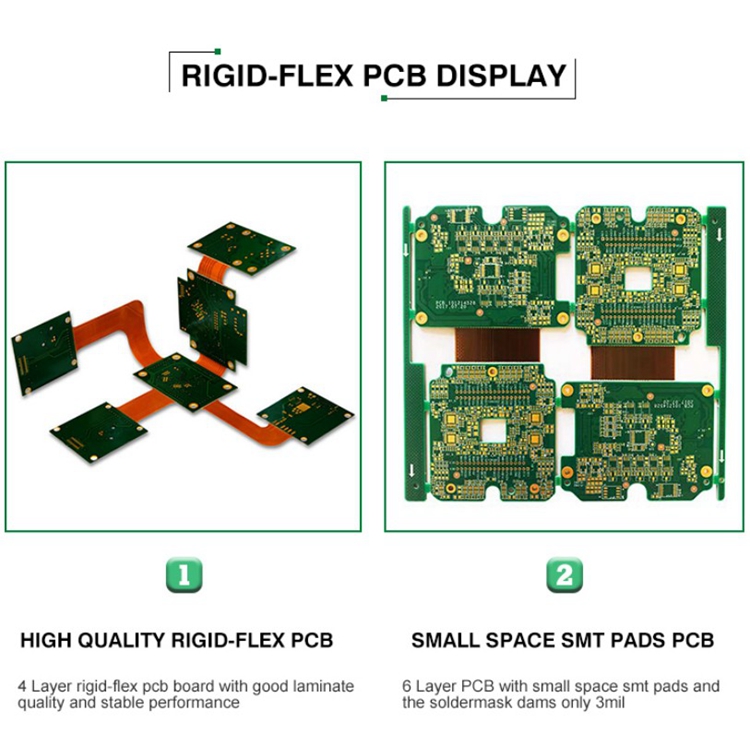

High Quality Flex Printed Circuit Boards and Rigid Circuit Pcb Boards:

4 Layer rigid-flex pcb board with good laminat equality and stable performance.

Small Space SMT Pads Pcb:

6 Layer PCB with small space smt pads and the solder mask dams only 3mil.

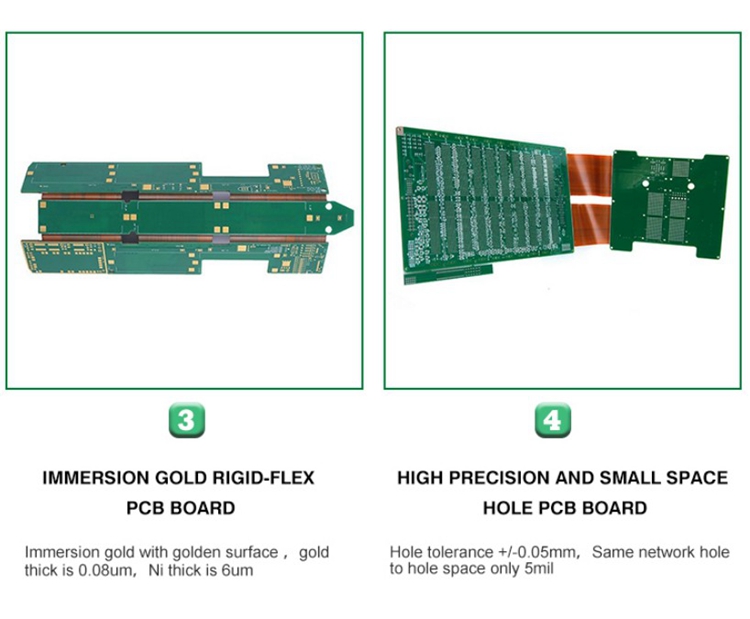

3 Immersion Gold Flex Printed Circuit Boards and Rigid Circuit Pcb Boards:

lmmersion gold with golden surface , gold thick is 0.08um. Ni thick is 6um.

High Precision And Small Space Hole Pcb Board:

Hole tolerance +/-O.05mm.Same network holeto hole space onlly 5mill. Get a quotation.

High Quality Fpc Pcb Board: with high speed transmission current stable,flexible,easy to install,good insulation.

Flexible Pcba Board: export led pcb board,PI material,Electrolytic copper,ultra-thin thickness,can be bent at will.

Double Sided Flex Pcb Manufacturer: connection line+PI reinforcement+tin spraying process.

Material: conductive adhesive, shielding film,resistance to winding capacity of more than 150,000 times.

1. Assembly Error Reduction – With accurate designs and automated production, flex circuits eliminate human errors once involved in hand-built wire harnesses. With the exception of production-induced errors, circuits are ONLY routed to those points called for by the accurate design plan.

2. Decreased Assembly Time and Costs – Flex circuits require less manual labor during assembly and reduce production errors. Flex circuits have an intrinsic ability to integrate form, fit and function. Flex circuits eliminate the high cost of routing, wrapping and soldering wires. Complete interconnection systems are installed or replaced, rather than individual hard PC boards. As a result, wiring errors are eliminated and hence manufacturing costs are reduced. Whether it is a low volume production with a complex circuit or high volume production with a simple circuit, assembly time and costs are decreased.

3. Design Freedom – Unlike rigid boards, flex circuits are not restricted to two dimensions. Because they are as flexible as wires or ribbon cables, flex circuit design options are endless. At Flexible Circuit, we pride ourselves on taking on the most complex of design challenges. Flex circuits can be designed to meet highly complex and unimaginable configurations while being able to operate in the most hostile environments.

Topfast Rigid Flex fpc pcb board with high precession.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China